The advantage of using glass process plant and pipeline components as a basis for the construction of complete process systems have long been recognized throughout the world’s chemical, pharmaceutical, food and drink and allied industries.

All the glass components detailed in this catalogue are manufactured exclusively from borosilicate glass type 3.3. Its principal features are its almost universal resistance to corrosion and its low coefficient of thermal expansion which allows great thermal strength and resistance to thermal shock.

Borosilicate glass plant and pipeline is used in both internal pressure and vacuum applications.

- Smooth non-porous surface

- Transparency

- Outstanding corrosion resistance

- No adverse physiology properties

- Neutral smell & taste

- Non-flammability

- Catalytic inertness

Thermal Shock

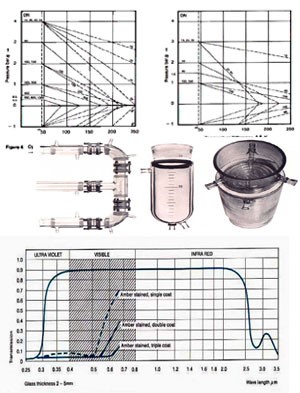

The permissible values for working temperature and pressure must always be considered together as thermal stresses resulting from high temperature differences between the inner and outer glass surfaces reduce the permissible working pressure (see Figures 3 to 8). If the internal temperature is less than the external – For example: in low temperature applications or for vessels with external heating – the thermal stresses require detailed consideration and we recommend that our Technical Department is consulted

Borosilicate glass retains its mechanical strength and will deform only at temperature, which approach its strain point, approximately 510°C. The permissible operating temperature is, however, considerably lower – normally at about 200°C – for glass components, provided that there is no temperature shock.

In exceptional circumstances, higher temperatures can be achieved possibly up to 300°C (see AD-N4). However, additional precautions are required and we recommend that our technical department is again consulted.

At sub-zero temperatures, the tensile strength of borosilicate glass tends to increase and equipment can be used at temperatures as low as -50°C.

These temperature limits should be regarded only as a guideline and must always be modified in accordance with the actual operating conditions in any given application. The individual operating condition of some of the components detailed in this catalogue must also be considered. Where such operating limits apply, they are detailed in the individual catalogue section and component description Under normal operating conditions, rapid changes in temperature should be avoided as this will result in increased stress in the glass. Experience has shown however that under exceptional conditions, a degree of thermal shock can be tolerated. It is undesirable to give an overall figure but, as a general guide, sudden temperature change of up to around 120°C can be accommodated

Depending on the shape and working conditions, glass components can be used, under certain circumstance, at higher internal pressure. In these cases, the component will be marked in accordance with AD-N4.

In cases where glass in operated under a gas pressure or vacuum we are recommending that our technical department is consulted for further information on suitable external protection.

Borosilicate glass retains its mechanical strength and will deform only at temperatures which approach its strain point. The practical upper limit for operating temperatures is much lower and is controlled by the temperature differentials in the glass, which depend on the relative temperatures of the contents of the equipment and the external surroundings.

Provided borosilicate glass is not subjected to rapid change in temperature, creating undue thermal shock, it can be operated safely at temperatures up to 4500F (232ºC). The normal limiting factor is actually the gasket material. The degree of thermal shock (usually defined as sudden chilling) which it can withstand depends on many factors, for example: stresses due to operating conditions; stresses imposed in supporting the equipment; the wall thickness of the glass, etc.

It is therefore undesirable to give an overall figure but, as a general guide, sudden temperature changes of up to about 216ºF (120ºC) can be accommodated At sub-zero temperatures, the tensile strength of borosilicate glass tends to increase and equipment can be used with safety at cryogenic temperatures It is always advisable to discuss any difficult applications with our engineers

The borosilicate glass used in the manufacture of our range of process plant and pipe line components has the following approximate composition.

| Component | % by weight |

|---|---|

| SiO² | 80.6 |

| B²O³ | 12.5 |

| Na²O | 4.2 |

| Al²O³ | 2.2 |

| Others | 0.5 |

Borosilicate glass is resistant to almost all substances except hydrofluoric acid, phosphoric acid and hot strong caustic solutions. Of these, hydrofluoric acid has the most serious effect and, even when a solution contains a few parts per million, corrosion will occur.

Phosphoric acid and caustic solution cause no problem when cold but at elevated temperatures corrosion occurs. Caustic solution up to 30% concentration can be handled safely at ambient temperature. Under actual service conditions, the effect of turbulence and traces of other chemical is the solution may increase or decrease the rate of attack.

With borosilicate glass, the transmission of ultra-violet light – which is the great importance for photo-chemical reaction- is somewhat greater in the middle spectrum that with normal window glass.

If photosensitive substances are being processed, the glass can be amber stained to special order. This permanent coating reduces the ultra violet light transmission to a minimum. Figure 2 shows a comparison of the light transmission for plain and amber glass.

The glass process plant and pipeline components detailed in this catalogue have either standard flat buttress ends (Type A + B from DN 25 to DN 450)

The following table provides dimensional information on standard flat buttress.

| DN(mm) | D1(mm) | D2(mm) |

|---|---|---|

| 25 | 26.5 | 42 |

| 40 | 38.5 | 57 |

| 50 | 50 | 69 |

| 80 | 76 | 99 |

| 100 | 104 | 132.5 |

| 150 | 154 | 185 |

| 225 | 229 | 258 |

| 300 | 308 | 340 |

| 450 | 462 | 535 |

Jacketed components are designed to complement the standard range of glass process plant and pipeline equipment’s detailed in this catalogue by extending the range of applications for which glass can be used. Jacketed components, as their name implies, are standard glass components with a glass jacket around them. The jacket is sealed onto the glass component with silicone rubber.

Jacketed components are not only used to avoid heat loss for the purpose of saving energy, but also where the product characteristics have to be maintained to prevent crystallizing or unwanted reactions from occurring. A further area of application is thermal insulation where the ability to still monitor the process visually is a major advantage.

Jacketed versions of all the major glass components detailed in this catalogue are available. The range therefore includes pipeline components, valves and vessels as well as a wide variety of column components and heat exchangers.