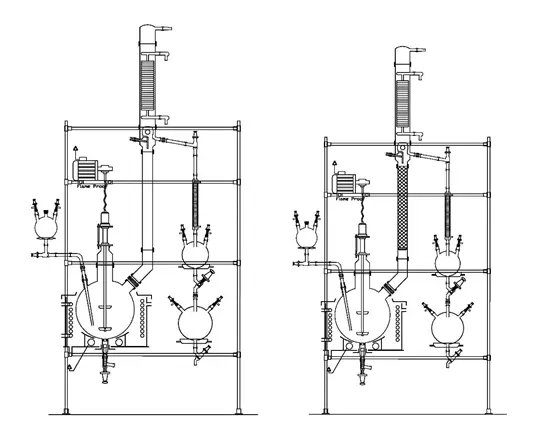

- The Unit Has Designed for The Manufacturers of the Fine Chemical & Pharmaceutical Companies to Use It as Reaction Unit, Distillation Unit or Combination of Pilot Plant for Batch Chemical Preparation.

- This Unit Can Work at Atmospheric Pressure as Well as Under Vacuum. Typical Unit Has a Reaction Vessel Fitted in Heating/Cooling Bath Having Facility for Heating or Cooling Both by Means of Heating/Cooling Fluids as Media.

- Twin Receivers Are Arranged to Enable Distillate to Be Removed While Unit Is Under Vacuum.

- Stirrer Having Mechanical Seal Is Mounted at Center Neck, Plain Column/Packed Column On Side Neck of the Vessel, Reflux Divider, Coil Type Heat Exchanger & Vent at Top for Removing Excess Vapor.

- Liquid Addition Line Is Also Provided for Liquid Charging in The Batch

- Receiver System Having Product Cooler, Receiver Vessel, Drain Valve & Vent Valve for Controlling Vacuum.

- The Above Is Supplied from 10LTR to 200ltr. In Spherical Shape 100LTR, 200ltr & 500ltr Can Be Supplied in Cylindrical Shape as Well.

- Variable Frequency Drive for Motor Can Be Supplied On Request.